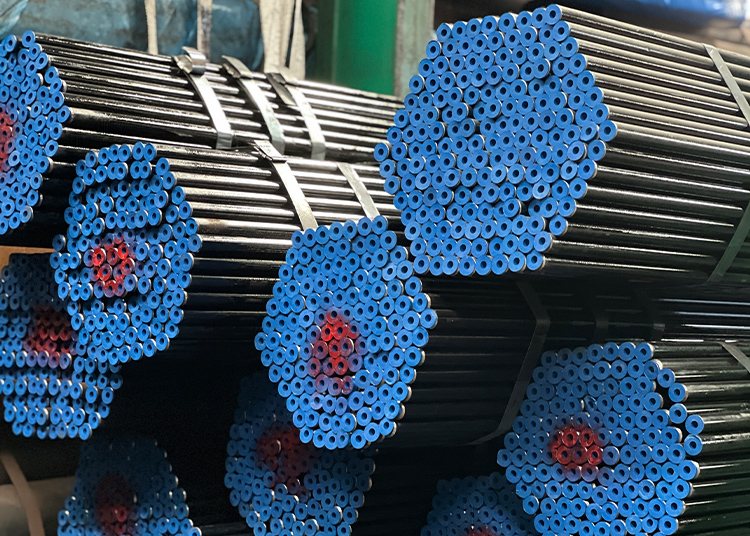

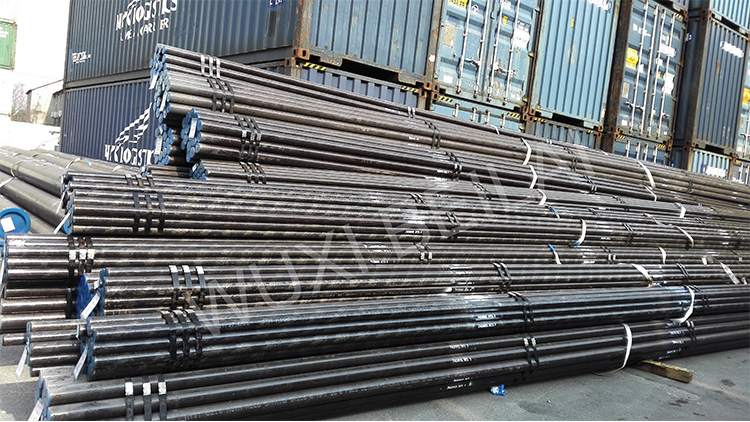

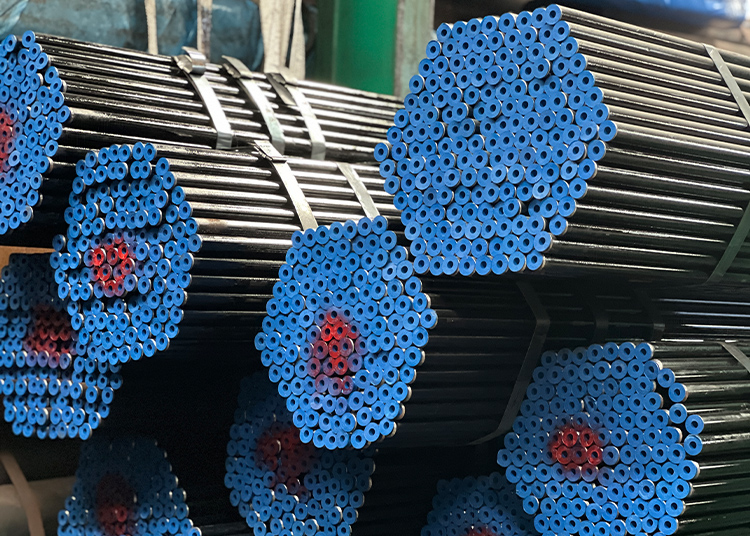

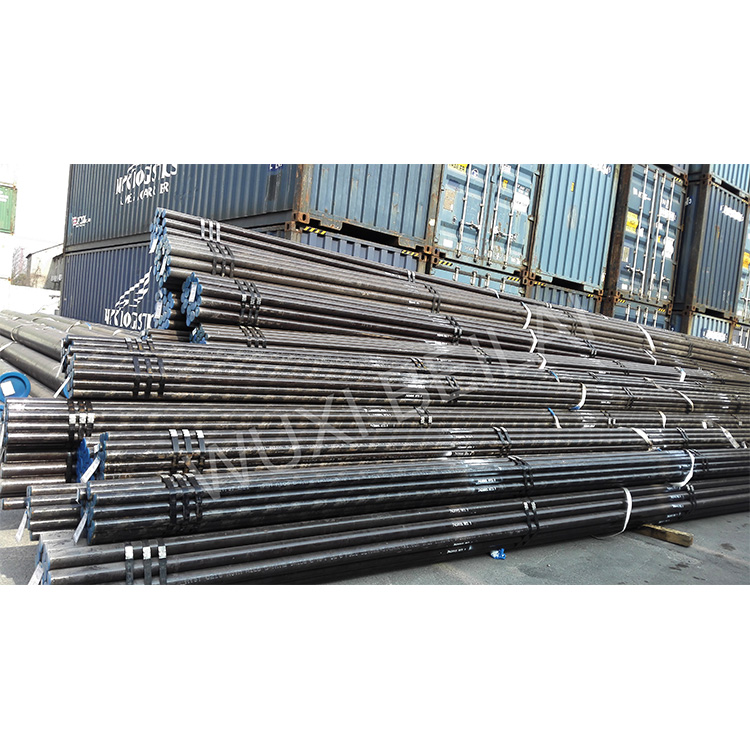

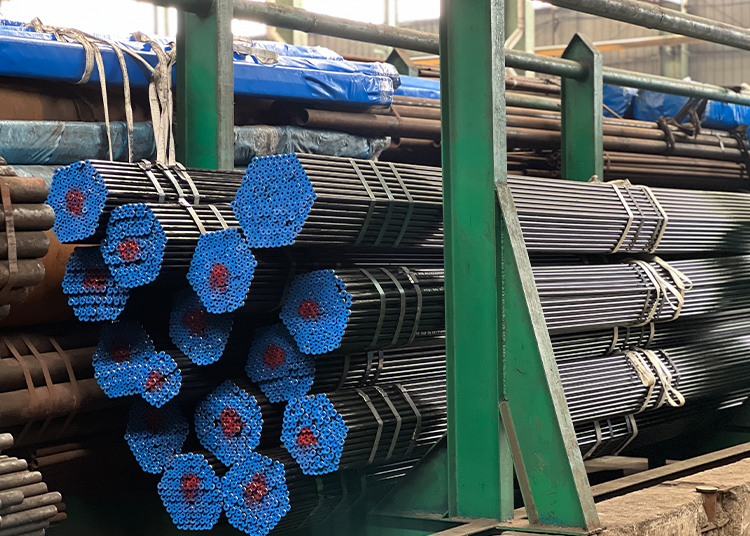

ISO 3183 LINE PIPE

- BEILAI

- CHINA

Line Pipe according to ISO 3183

ISO 3183:2012 specifies requirements for the manufacture of two product specification levels (PSL 1 and PSL 2) of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries. Beilai Produce line pipes according to ISO 3183:2012.

Standards and technical terms of products

API SPEC 5L Specification for line pipe

ISO 3183 Petroleum and natural gas industries-steel pipe for pipeline transportation system.

GB/T9711 Pipe line used for transport system in oil and gas industry

ASME B36.10 Welded and seamless wrought steel pipe

ANSI/NACE MR0175 Metals for sulfide stress cracking and stress corrosion cracking resistance in sour oilfield

ANSI/NACE TM0177 Laboratory testing of metal for resistance to sulfide stress cracking and stress Corrosion cracking in H2S environment

ISO15156 Petroleum and natural gas industries -materials for use in H2S containing environment in oil and gas production

Size

OD: Ø21.3mm- Ø219.1mm, wall thickness:2.77mm-22.23mm

DN(mm) | NPS(in) | OD(mm) | 10 | 20 | 30 | STD/40 | 60 | XS/80 | 100 | 120 | 140 | 160 | XXS |

15 | 1/2 | 21.3 | 2.77 | 3.73 | 4.78 | 7.47 | |||||||

20 | 3/4 | 26.7 | 2.87 | 3.91 | 5.56 | 7.82 | |||||||

25 | 1 | 33.4 | 3.38 | 4.55 | 6.35 | 9.09 | |||||||

32 | 1 1/4 | 42.2 | 3.58 | 4.85 | 6.35 | 9.70 | |||||||

40 | 1 1/2 | 48.3 | 3.68 | 5.08 | 7.14 | 1.015 | |||||||

50 | 2 | 60.3 | 3.91 | 5.54 | 8.74 | 11.07 | |||||||

65 | 2 1/2 | 73.0 | 5.16 | 7.01 | 9.53 | 14.02 | |||||||

80 | 3 | 88.9 | 5.49 | 7.62 | 11.13 | 15.24 | |||||||

90 | 3 1/2 | 101.6 | 5.74 | 8.08 | |||||||||

100 | 4 | 114.3 | 6.02 | 8.56 | 11.13 | 13.49 | 17.12 | ||||||

125 | 5 | 141.3 | 6.55 | 9.53 | 12.70 | 15.88 | 19.05 | ||||||

150 | 6 | 168.3 | 7.11 | 10.97 | 14.27 | 18.26 | 21.95 | ||||||

200 | 8 | 219.1 | 6.35 | 7.04 | 8.18 | 10.31 | 12.70 | 15.08 | 18.26 | 20.62 | 23.01 | 22.23 |

Chemical composition

Grade | Chemical composition/% Max | |||||||

C | Si | Mn | P | S | V | Nb | Ti | |

L245/B | 0.28 | - | 1.20 | 0.030 | 0.030 | - | - | - |

L290/X42 | 0.28 | - | 1.30 | 0.030 | 0.030 | - | - | - |

L320/X46 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

L360/X52 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

L390/X56 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

L415/X60 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

L450/X65 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

L485/X70 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

Note: Date in the composition of PSL1:PSL2 The composition can be negotiated by both parties | ||||||||

Mechanical property requirements

Grade | Yield strength/Mpa | Yield strength/Mpa | Yield ratio | CVN/J | ||||||

PSL1(Min) | PSL2 | PSL1(Min) | PSL2 | PSL1(Min) | PSL2 | |||||

-N,Q | -NS,QS | -N,Q | -NS,QS | -N,Q | -NS,QS | |||||

L245/B | 245 | 245~450 | 245~450 | 415 | 415~655 | 415~655 | - | ≤0.93 | ≤0.93 | ≥27 |

L290/X42 | 2900 | 290~495 | 290~495 | 415 | 415~655 | 415~655 | - | |||

L320/X46 | 320 | 320~525 | 320~525 | 435 | 435~655 | 435~655 | - | |||

L360/X52 | 360 | 360~530 | 360~530 | 460 | 460~760 | 460~760 | - | |||

L390/X56 | 390 | 390~545 | 390~545 | 490 | 490~760 | 490~760 | - | |||

L415/X60 | 415 | 415~565 | 415~565 | 520 | 520~760 | 520~760 | - | |||

L450/X65 | 450 | 450~600 | 450~600 | 535 | 535~760 | 535~760 | - | |||

L485/X70 | 485 | 485~635 | 485~635 | 570 | 570~760 | 570~760 | - | |||

L555/X80 | 555~705 | 625~825 | ≥40 | |||||||

Note:Line pipe for other special service environment will be manufactured based on the negotiation resule of both sides. | ||||||||||