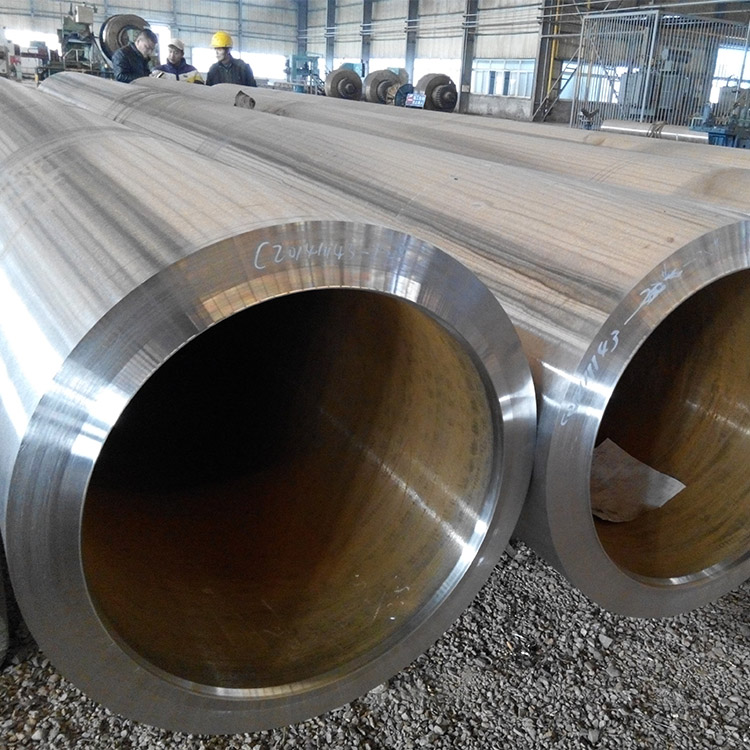

A335 & A335M ALLOY-STEEL PIPE

- BEILAI

- CHINA

A335 & A335M Alloy Steel Pipe Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service1

Sizes: 1/8" to 24”

WT Schedules: SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS to SCH 160. SCH XXS

Because of its unique material characteristics, alloy steel pipe has been widely used in many fields. It is mainly used in oil and gas industry, power industry, chemical industry, machinery manufacturing and energy field

Chemical Requirements

| Grade | UNS DesignationA | Composition, % | |||||||

| Carbon | Manganese | Phosphorus max | Sulfur max | Silicon | Chromium | Molybdenum | Others | ||

| P1 | K11522 | 0.10-0.20 | 0.30-0.80 | 0.025 | 0.025 | 0.10-0.50 | / | 0.44-0.65 | / |

| P2 | K11547 | 0.10-0.20 | 0.30-0.61 | 0.025 | 0.025 | 0.10-0.30 | 0.50–0.81 | 0.44-0.65 | / |

| P5 | K41545 | 0.15 max | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 4.00–6.00 | 0.45-0.65 | / |

| P5b | K51545 | 0.15 max | 0.30-0.60 | 0.025 | 0.025 | 1.00-2.00 | 4.00–6.00 | 0.45-0.65 | / |

| P5c | K41245 | 0.12 max | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 4.00–6.00 | 0.45-0.65 | B |

| P9 | K90941 | 0.15 max | 0.30-0.60 | 0.025 | 0.025 | 0.25-1.00 | 8.00–10.00 | 0.90-1.10 | / |

| P11 | K11597 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50-1.00 | 1.00–1.50 | 0.44-0.65 | / |

| P12 | K11562 | 0.05-0.15 | 0.30-0.61 | 0.025 | 0.025 | 0.50 max | 0.80–1.25 | 0.44-0.65 | / |

| P15 | K11578 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.15-1.65 | / | 0.44-0.65 | / |

| P21 | K31545 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 2.65–3.35 | 0.80-1.06 | / |

| P22 | K21590 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 1.90-2.60 | 0.87-1.13 | / |

| P23 | K40712 | 0.04-0.10 | 0.10-0.60 | 0.030 max | 0.010 max | 0.50 max | 1.90-2.60 | 0.05-0.30 | V 0.20–0.30 |

| P24 | K30736 | 0.05-0.10 | 0.30-0.70 | 0.02 | 0.01 | 0.15-0.45 | 2.20-2.60 | 0.90-1.10 | V 0.20–0.30 |

| P36 | K21001 | 0.10-0.17 | 0.80-1.20 | 0.030 max | 0.025 max | 0.25-0.50 | 0.30 max | 0.25-0.50 | Ni 1.00-1.30 |

| P91 Type 1 | K91560 | 0.08-0.12 | 0.30-0.60 | 0.02 | 0.01 | 0.20-0.50 | 8.00-9.50 | 0.85-1.05 | V 0.18–0.25 |

| P91 Type 2 Heat Product | K91560 | 0.08-0.12 0.07-0.13 | 0.30–0.50D | 0.020D | 0.005D | 0.20-0.40D | 8.00-9.50D | 0.85-1.05 0.80-1.05 | Heat 0.18–0.25 |

| P92 | K92460 | 0.07-0.13 | 0.30–0.60 | 0.02 | 0.01 | 0.50 max | 8.50-9.50 | 0.30-0.60 | V 0.15–0.25 |

| P93 | K91350 | 0.05-0.10 | 0.50-0.70 | 0.02 | 0.008 | 0.05-0.50 | 8.50-9.50 | / | V 0.15–0.30 |

| P115 Heat | K91060 | 0.08-0.13 | 0.20-0.50 | 0.02 | 0.005 | 0.15-0.45 | 10.0-11.0 | 0.40-0.60 | V 0.18–0.25 |

| Product | / | 0.07-0.14 | 0.50-0.50 | 0.02 | 0.005 | 0.15-0.45 | 10.0-11.0 | 0.37-0.63 | V 0.16–0.27 |

| P122 | K92930 | 0.07-0.14 | 0.70 max | 0.02 | 0.01 | 0.50 max | 10.00-11.50 | 0.25-0.60 | V 0.15–0.30 |

| P128 | K91421 | 0.12-0.17 | 0.30-0.80 | 0.02 | 0.01 | 0.20-0.60 | 10.50-12.00 | 0.20-0.60 | V 0.15 – 0.30 |

| P911 | K91061 | 0.09-0.13 | 0.30-0.60 | 0.020 max | 0.010 max | 0.10-0.50 | 8.5-9.5 | 0.90-1.10 | V 0.18–0.25 |

| P921 | K91201 | 0.08-0.12 | 0.5-0.7 | 0.03 | 0.02 | 1.6-2.2 | 8.0-9.5 | 0.8-1.1 | Ni 0.8–1.4 |

ANew designation established in accordance with Practice E527 and SAE J1086, Practice for Numbering Metals and Alloys (UNS).

BGrade P5c shall have a titanium content of not less than 4 times the carbon content and not more than 0.70 %; or a niobium content of 8 to 10 times the carbon content.

Heat Treatment RequirementsA

| Grade | Heat Treat Type | Normalizing Temperature, min or range °F [°C] | Cooling Media | Subcritical Annealing or Tempering Temperature, min or range °F [°C] |

| P1 | full or isothermal anneal or | / | / | / |

| normalize and temper or | / | / | 1200 [650] | |

| subcritical anneal | / | / | 1200–1300 [650–705] | |

| P2 | full or isothermal anneal or | / | / | / |

| normalize and temper or | / | / | 1200 [650] | |

| subcritical anneal | / | / | 1200–1300 [650–705] | |

| P5 | full or isothermal anneal or | / | / | / |

| normalize and temper or | / | / | 1250 [675] | |

| P5b | full or isothermal anneal or | / | / | / |

| normalize and temper or | / | / | 1250 [675] | |

| P5c | subcritical annea | / | / | 1325–1375 [715–745] |

| P9 | full or isothermal anneal or | / | / | / |

| normalize and temper | / | / | 1250 [675] | |

| P11 | full or isothermal anneal or | / | / | / |

| normalize and temper | / | / | 1250 [650] | |

| P12 | full or isothermal anneal or | / | / | / |

| normalize and temper or | / | / | 1200 [650] | |

| subcritical anneal | / | / | 1200–1300 [650–705] | |

| P15 | full or isothermal anneal or | / | / | / |

| normalize and temper | / | / | 1200 [650] | |

| P21 | full or isothermal anneal or | / | / | / |

| normalize and temper | / | / | 1250 [675] | |

| P23 | normalize and temper | 1900–1975 [1040–1080] | air or accelerated cooling | 1350–1470 [730–800] |

| P24 | normalize and temper | 1800–1870 [980–1020] | air or accelerated cooling | 1350–1420 [730–770] |

| P36 | normalize and temperB | 1650 [900] | / | 1100 [595] |

| P91 Type 1 and Type 2 | normalize and temper or | 1900–1975 [1040–1080] | / | 1350–1470 [730–800]C |

| quench and temper | 1900–1975 [1040–1080] | / | 1350–1470 [730–800] | |

| P92 | normalize and temper | 1900–1975 [1040–1080] | D | 1350–1470 [730–800] |

| P93 | normalize and temper | 1960–2140 [1070–1170] | / | 1380–1455 [750–790] |

| P115 | normalize and temper | 1920–2010 [1050–1100] | D | 1380–1455 [750–790] |

| P122 | normalize and temper | 1900–1975 [1040–1080] | / | 1350–1470 [730–800] |

| P128 | normalize and temper | 1975–2140 [1080–1170] | air | 1400–1470 [760–800] |

| P911 | normalize and temper | 1900–1975 [1040–1080] | D | 1365–1435 [740–780] |

| P921 | normalize and temper | 1670–1740 [910–950] | air | 1350–1420 [730–770] |

AWhere ellipses ({) appear in this table there is no requirement.

BAlternatively, Grade P36, Class 2 shall be cooled from the austenitizing temperature by accelerated cooling in air or by liquid quenching.

CExcept when Supplementary Requirement S7 is specified by the purchaser.

DAccelerated cooling from the normalizing temperature shall be permitted for section thicknesses greater than 3 in. [75 mm].

Tensile Requirements

| Grade | ||||||||||||

| P1,P2 | P12 | P23 | P24 | P91 Type 1 and Type 2 | P92,P93,P911,P36 Class1 | P921 | P115 | P122 | P128 | P36 Class2 | All Others | |

| Tensile strength,min: | ||||||||||||

| ksi | 55 | 60 | 74 | 85 | 85 | 90 | 109 | 90 | 90 | 94 | 95.5 | 60 |

| Mpa | 380 | 415 | 510 | 585 | 585 | 620 | 750 | 620 | 620 | 650 | 660 | 415 |

| Yield strength,min: | ||||||||||||

| ksi | 30 | 32 | 58 | 60 | 60 | 64 | 84 | 65 | 58 | 71 | 66.5 | 30 |

| Mpa | 205 | 220 | 400 | 415 | 415 | 440 | 580 | 450 | 400 | 490 | 460 | 205 |