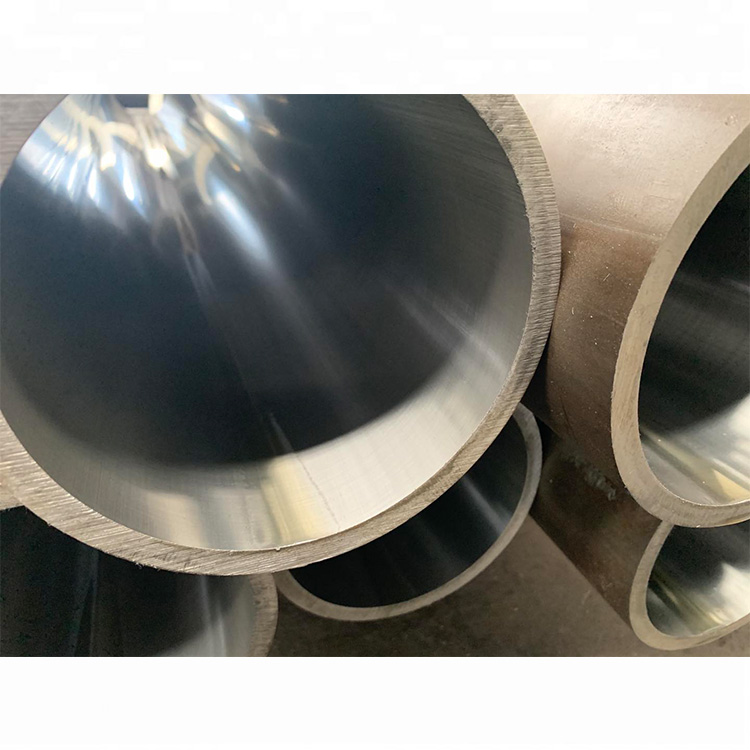

ASTM A106 & A53

- BEILAI

ASTM A106/A106M:Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service

Application: Oil, Gas and water delivery; Refinery, Boiler and Mechanical equipment manufacturer; structure construction; drilling, ship building and etc.

ASTM A53/A53M:Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

Application: Oil, Gas and water delivery; Refinery, Boiler and Mechanical equipment manufacturer; structure construction; drilling, ship building and etc.

ASTM A106 Chemical Requirements | ||||||||

Grade | Composition, % | |||||||

C max | Mn | P max | S max | Si min | Cr max | Mo max | Others | |

A | 0.25 | 0.27–0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.15 | ... |

B | 0.3 | 0.29–1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.15 | ... |

C | 0.35 | 0.29–1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.15 | ... |

Mechanical Properties | |||

Grade | |||

A | B | C | |

Tensile strength, min: | |||

ksi | 48 | 60 | 70 |

Mpa | 330 | 415 | 485 |

Yield strength, min: | |||

ksi | 30 | 35 | 40 |

MPa | 205 | 240 | 275 |

Elongation Requirements: As per standard

Available Dimension Range | |||||||||||||

OD(mm/inch) | Wall thickness(SCH) | ||||||||||||

10 | 20 | 30 | STD | 40 | 60 | XS | 80 | 100 | 120 | 140 | 160 | XXS | |

21.3 (1/2'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

26.7 (3/4'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

33.4 (1'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

42.2 (1 1/4'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

48.3 (1 1/2'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

60.3 (2'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

73 (2 1/2'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

88.9 (3'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

101.6 (3 1/2'') | Δ | Δ | Δ | Δ | Δ | Δ | |||||||

114.3 (4'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | ||||

141.3 (5'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | ||||||

168.3 (6'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

219.1 (8'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ |

273 (10'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ |

323.8 (12'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ |

355.6 (14'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |

406.4 (16'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |

457 (18'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |

508 (20'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |

559 (22'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | ||

610 (24'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

660 (26'') | Δ | Δ | Δ | ||||||||||

711 (28'') | Δ | Δ | Δ | Δ | Δ | ||||||||

762 (30'') | Δ | Δ | Δ | Δ | Δ | ||||||||

813 (32'') | Δ | Δ | Δ | Δ | Δ | Δ | |||||||

864 (34'') | Δ | Δ | Δ | Δ | Δ | Δ | |||||||

914 (36'') | Δ | Δ | Δ | Δ | Δ | Δ | |||||||

ASTM A53 Chemical Requirements | ||||||||

Type | Grade | Composition % | ||||||

C | Mn | P | S | Cr | Mo | Others | ||

S | A | 0.25 | 0.95 | 0.05 | 0.045 | 0.4 | 0.15 | ... |

B | 0.30 | 1.20 | 0.05 | 0.045 | 0.4 | 0.15 | ... | |

E | A | 0.25 | 0.95 | 0.05 | 0.045 | 0.4 | 0.15 | ... |

B | 0.30 | 1.20 | 0.05 | 0.045 | 0.4 | 0.15 | ... | |

F | A | 0.30 | 1.20 | 0.05 | 0.045 | 0.4 | 0.15 | ... |

Mechanical Properties | ||

Grade | ||

A | B | |

Tensile strength, min: | ||

ksi | 48 | 60 |

Mpa | 330 | 415 |

Yield strength, min: | ||

ksi | 30 | 35 |

MPa | 205 | 240 |

Elongation Requirements:As per standard

Available Dimension Range

OD(mm/inch) | Wall thickness(SCH) | ||||||||||||

10 | 20 | 30 | STD | 40 | 60 | XS | 80 | 100 | 120 | 140 | 160 | XXS | |

21.3 (1/2'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

26.7 (3/4'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

33.4 (1'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

42.2 (1 1/4'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

48.3 (1 1/2'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

60.3 (2'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

73 (2 1/2'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

88.9 (3'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

101.6 (3 1/2'') | Δ | Δ | Δ | Δ | Δ | Δ | |||||||

114.3 (4'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | ||||

141.3 (5'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | ||||||

168.3 (6'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

219.1 (8'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ |

273 (10'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ |

323.8 (12'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ |

355.6 (14'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |

406.4 (16'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |

457 (18'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |

508 (20'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |

559 (22'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | ||

610 (24'') | Δ | Δ | Δ | Δ | Δ | Δ | Δ | Δ | |||||

660 (26'') | Δ | Δ | Δ | ||||||||||

711 (28'') | Δ | Δ | Δ | Δ | Δ | ||||||||

762 (30'') | Δ | Δ | Δ | Δ | Δ | ||||||||

813 (32'') | Δ | Δ | Δ | Δ | Δ | Δ | |||||||

864 (34'') | Δ | Δ | Δ | Δ | Δ | Δ | |||||||

914 (36'') | Δ | Δ | Δ | Δ | Δ | Δ | |||||||

*If the steel grades and size you are looking for are not listed above, please contact us for further information.