Nace TM0177 LINE PIPE

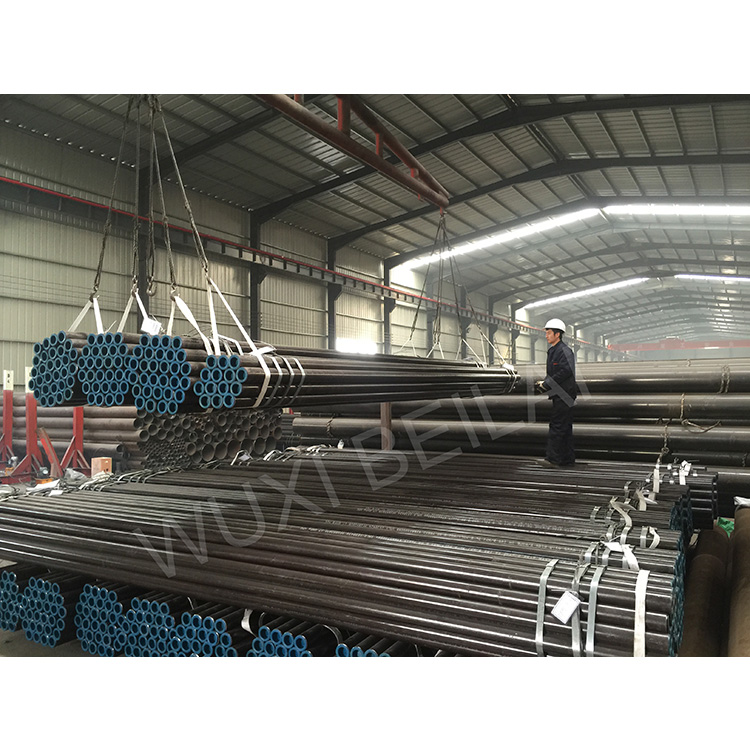

- BEILAI

- CHINA

Nace TM0177 Line Pipe

This standard addresses the testing of metals for resistance to cracking failure under the combined action of tensile stress and corrosion in aqueous environments containing hydrogen sulfide (H2S). Beilai Produce line pipes acoording to Nace TM0177.

Standards and technical terms of products

API SPEC 5L Specification for line pipe

ISO 3183 Petroleum and natural gas industries-steel pipe for pipeline transportation system.

GB/T9711 Pipe line used for transport system in oil and gas industry

ASME B36.10 Welded and seamless wrought steel pipe

ANSI/NACE MR0175 Metals for sulfide stress cracking and stress corrosion cracking resistance in sour oilfield

ANSI/NACE TM0177 Laboratory testing of metal for resistance to sulfide stress cracking and stress Corrosion cracking in H2S environment

ISO15156 Petroleum and natural gas industries -materials for use in H2S containing environment in oil and gas production

Size

OD: Ø21.3mm- Ø219.1mm, wall thickness:2.77mm-22.23mm

DN(mm) | NPS(in) | OD(mm) | 10 | 20 | 30 | STD/40 | 60 | XS/80 | 100 | 120 | 140 | 160 | XXS |

15 | 1/2 | 21.3 | 2.77 | 3.73 | 4.78 | 7.47 | |||||||

20 | 3/4 | 26.7 | 2.87 | 3.91 | 5.56 | 7.82 | |||||||

25 | 1 | 33.4 | 3.38 | 4.55 | 6.35 | 9.09 | |||||||

32 | 1 1/4 | 42.2 | 3.58 | 4.85 | 6.35 | 9.70 | |||||||

40 | 1 1/2 | 48.3 | 3.68 | 5.08 | 7.14 | 1.015 | |||||||

50 | 2 | 60.3 | 3.91 | 5.54 | 8.74 | 11.07 | |||||||

65 | 2 1/2 | 73.0 | 5.16 | 7.01 | 9.53 | 14.02 | |||||||

80 | 3 | 88.9 | 5.49 | 7.62 | 11.13 | 15.24 | |||||||

90 | 3 1/2 | 101.6 | 5.74 | 8.08 | |||||||||

100 | 4 | 114.3 | 6.02 | 8.56 | 11.13 | 13.49 | 17.12 | ||||||

125 | 5 | 141.3 | 6.55 | 9.53 | 12.70 | 15.88 | 19.05 | ||||||

150 | 6 | 168.3 | 7.11 | 10.97 | 14.27 | 18.26 | 21.95 | ||||||

200 | 8 | 219.1 | 6.35 | 7.04 | 8.18 | 10.31 | 12.70 | 15.08 | 18.26 | 20.62 | 23.01 | 22.23 |

Chemical composition

Grade | Chemical composition/% Max | |||||||

C | Si | Mn | P | S | V | Nb | Ti | |

L245/B | 0.28 | - | 1.20 | 0.030 | 0.030 | - | - | - |

L290/X42 | 0.28 | - | 1.30 | 0.030 | 0.030 | - | - | - |

L320/X46 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

L360/X52 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

L390/X56 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

L415/X60 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

L450/X65 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

L485/X70 | 0.28 | - | 1.40 | 0.030 | 0.030 | - | - | - |

Note: Date in the composition of PSL1:PSL2 The composition can be negotiated by both parties | ||||||||

Mechanical property requirements

Grade | Yield strength/Mpa | Yield strength/Mpa | Yield ratio | CVN/J | ||||||

PSL1(Min) | PSL2 | PSL1(Min) | PSL2 | PSL1(Min) | PSL2 | |||||

-N,Q | -NS,QS | -N,Q | -NS,QS | -N,Q | -NS,QS | |||||

L245/B | 245 | 245~450 | 245~450 | 415 | 415~655 | 415~655 | - | ≤0.93 | ≤0.93 | ≥27 |

L290/X42 | 2900 | 290~495 | 290~495 | 415 | 415~655 | 415~655 | - | |||

L320/X46 | 320 | 320~525 | 320~525 | 435 | 435~655 | 435~655 | - | |||

L360/X52 | 360 | 360~530 | 360~530 | 460 | 460~760 | 460~760 | - | |||

L390/X56 | 390 | 390~545 | 390~545 | 490 | 490~760 | 490~760 | - | |||

L415/X60 | 415 | 415~565 | 415~565 | 520 | 520~760 | 520~760 | - | |||

L450/X65 | 450 | 450~600 | 450~600 | 535 | 535~760 | 535~760 | - | |||

L485/X70 | 485 | 485~635 | 485~635 | 570 | 570~760 | 570~760 | - | |||

L555/X80 | 555~705 | 625~825 | ≥40 | |||||||

Note:Line pipe for other special service environment will be manufactured based on the negotiation resule of both sides. | ||||||||||